HEAT SHRINK CRIMP CONNECTOR

THE RIGHT SOLUTION

INTRODUCTION ON HOW TO USE HEAT SHRINK CRIMP CONNECTORS

Heat-shrink crimp connectors are essential components in creating reliable, long-lasting electrical connections in a variety of applications. These connectors combine two powerful techniques: crimping, which securely joins wires together, and heat shrinking, which ensures a waterproof, insulated seal around the connection. With their ability to provide protection against moisture, corrosion, and wear, heat-shrink crimp connectors are ideal for automotive, marine, household, and general electrical use. Easy to install and highly effective, they offer an added layer of durability, making them a go-to choice for both professional electricians and DIY enthusiasts alike.

AUTOMOTIVE USES

Automotive electrical systems are exposed to harsh environments, including fluctuating temperatures, vibrations, and moisture. Ensuring secure and reliable connections in such conditions is crucial for the proper functioning of a vehicle’s electrical components. Heat shrink crimp connectors are an ideal solution for automotive wiring because they provide both a strong, durable connection and an extra layer of protection against environmental factors.

Step-by-Step Guide for Installation in Automotive Applications:

Preparation:

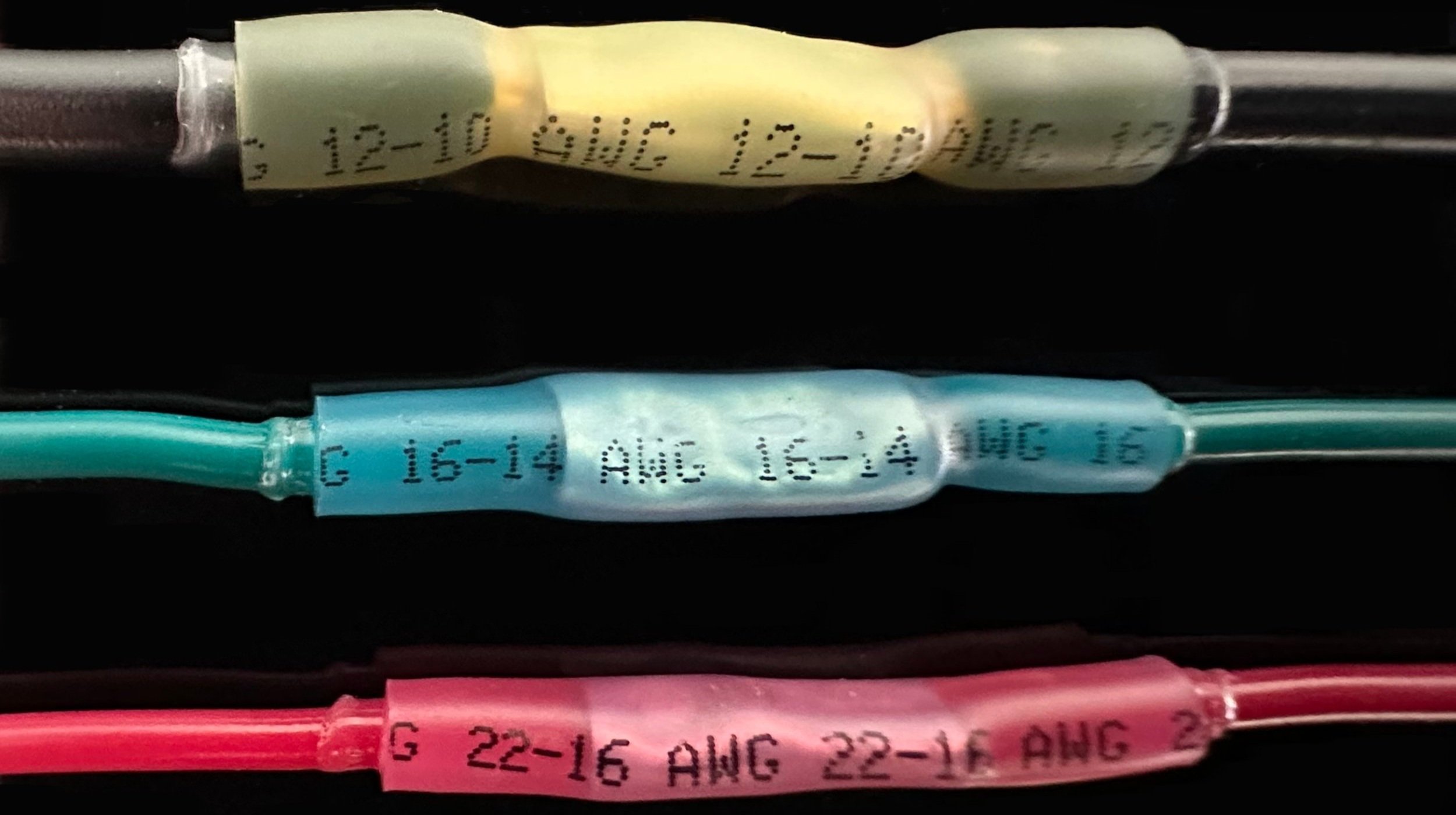

Begin by stripping the insulation from the ends of the wires. Be sure to leave enough exposed wire to insert fully into the connector, but avoid over-stripping, as this could lead to a poor connection. Use a wire stripper to create clean, uniform cuts that will make crimping more effective.Choosing the Right Connector:

Automotive wiring often involves different wire gauges depending on the application, so it’s essential to select a connector that matches the wire size. Over-sized connectors can lead to loose connections, while undersized connectors can cause electrical failures. Many heat shrink crimp connectors come in color-coded options to indicate the appropriate wire gauge.Crimping the Connector:

Insert the stripped wire into the crimp connector and use a crimping tool to secure it. Ensure that the crimp tool makes a firm, even press, so that the metal crimp securely grips the wire without damaging it. A poor crimp can lead to weak or intermittent electrical connections, so it’s important to check the crimp for tightness.Shrinking the Tubing:

After the wire is securely crimped into the connector, slide the heat shrink tubing over the crimped area. Using a heat gun, apply heat evenly across the tubing. The tubing will shrink as it heats up, creating a tight seal around the connector and protecting the connection from moisture, dirt, and corrosion. Be sure to avoid overheating the tubing, as this could damage the wire or connector.Testing the Connection:

After shrinking the tubing, test the connection by gently pulling on the wires to ensure they are secure. Additionally, use a multimeter to check the continuity and confirm that the electrical connection is functioning properly. In automotive systems, it’s also advisable to test the connection under load to ensure it can handle the electrical demand.

Why Automotive Applications Benefit from Heat Shrink Connectors:

Vibration Resistance: Heat shrink connectors provide extra security in high-vibration environments, such as under the hood of a car, where loose connections can lead to electrical failure or even fires.

Waterproofing: Many automotive systems are exposed to water (e.g., rain, snow, or engine cooling fluids). The heat shrink tubing forms a tight seal that prevents moisture from entering the connection, reducing the risk of corrosion.

Durability: The tough outer layer of heat shrink tubing offers protection against abrasion and general wear, making it ideal for automotive components that are exposed to friction or rough surfaces.

Improved Safety: Properly sealed connections are less likely to short out, ensuring the safety of both the vehicle and its occupants. The shrink tubing also helps reduce the chances of electrical fires, a serious concern in automotive systems.

Additional Tips for Automotive Use:

Always disconnect the battery before working on the vehicle’s electrical system to avoid electrical shocks or accidental short circuits.

Check for any signs of wear or damage in connectors that may need replacement.

Make sure that all wires are properly insulated and secured to prevent them from becoming loose or exposed to damaging elements.

By using heat shrink crimp connectors, automotive professionals and DIYers can ensure that their vehicle’s electrical systems remain reliable and safe, even in the most challenging conditions.

HOUSEHOLD USES

In household electrical systems, maintaining secure and safe connections is essential to ensuring the proper functioning of lighting, appliances, and other devices. Whether you’re wiring a new outlet, repairing a faulty connection, or working on DIY electrical projects, heat shrink crimp connectors are a reliable solution for creating strong, insulated, and secure electrical connections. These connectors are especially useful in environments where moisture or other elements might compromise the integrity of traditional connectors.

Step-by-Step Guide for Installation in Household Applications:

Preparation:

Begin by stripping the insulation from the wires to expose the bare metal. Use a wire stripper to carefully remove just enough insulation to make a secure connection without damaging the wire. It’s important to ensure that the stripped wire matches the length required for a proper crimp connection.Choosing the Right Connector:

Household wiring typically uses a range of wire gauges, depending on the appliance or device. It’s crucial to select heat shrink crimp connectors that match the wire gauge you’re working with. Many connectors come in color-coded variations, which makes it easier to select the correct size based on the wire thickness.Crimping the Wires:

Insert the stripped wire into the crimp connector and use a crimping tool to compress the metal connector around the wire. A firm, uniform crimp ensures that the wire is tightly held and will not come loose over time. Make sure that the crimp does not cut into the wire strands or leave gaps, as this can result in an unreliable connection.Shrinking the Tubing:

After crimping the connector onto the wire, slide the heat shrink tubing over the crimped area. Use a heat gun to evenly apply heat to the tubing. The heat will cause the tubing to shrink tightly around the connection, forming a protective seal. Be careful not to overheat the tubing, as this could cause it to shrink too quickly or burn.Testing the Connection:

Once the tubing has shrunk and formed a secure seal, gently tug on the wires to ensure they are securely attached. For added assurance, use a multimeter to check the connection for continuity, ensuring that the electrical path is intact and the connection is functioning correctly.

Why Household Applications Benefit from Heat Shrink Crimp Connectors

Safety and Security: Properly insulated and crimped connectors reduce the risk of electrical shorts or exposed wires that could lead to fires. Heat shrink tubing provides an extra layer of protection, keeping the connection safely insulated.

Moisture Protection: In areas of the home where moisture is a concern, such as kitchens, bathrooms, or basements, the added waterproof seal from the heat shrink tubing helps prevent water from entering the connection, reducing the risk of corrosion or electrical failure.

Long-lasting Durability: Heat shrink crimp connectors offer strong, reliable connections that last longer than traditional wire nuts or other connectors, even in environments with frequent temperature fluctuations or wear and tear.

Ease of Use for DIY Projects: For homeowners working on electrical repairs or projects, heat shrink crimp connectors provide a simple and effective way to make secure electrical connections without needing advanced tools or professional expertise.

Common Household Uses for Heat Shrink Crimp Connectors:

Electrical Repairs: If an electrical wire in your home becomes frayed or disconnected, using heat shrink crimp connectors can restore the connection and prevent any safety hazards.

Appliance Wiring: Whether it’s for a refrigerator, washing machine, or another household appliance, heat shrink connectors can ensure secure connections between internal components, protecting against potential electrical issues.

Lighting Fixtures: Wiring light fixtures, including ceiling lights or outdoor lighting systems, is a common use for these connectors, ensuring safe, durable connections that won’t easily come loose.

Automated Systems: Home automation systems, like smart home hubs or security systems, often require solid and safe electrical connections, which heat shrink connectors can provide.

Additional Tips for Household Use:

Power Off: Always turn off the power supply to the electrical system you’re working on to prevent electrical shocks or short circuits.

Check for Compatibility: Ensure that the heat shrink connectors you choose are rated for the voltage and current that your household system uses. This will help prevent overheating and potential electrical issues.

Inspect Connections Regularly: Over time, it’s a good practice to inspect any electrical connections in your home for wear, corrosion, or damage, especially in high-humidity environments.

Troubleshooting Common Issues:

Loose Crimp: If the wire is not securely crimped, it could result in a weak connection that might cause electrical issues. Always ensure the crimp tool is applied firmly to create a tight connection.

Insufficient Shrinkage: If the heat shrink tubing doesn’t shrink properly, reapply heat or check for any obstructions in the tubing that might prevent it from shrinking. Always use the recommended temperature settings for your heat gun.

By using heat shrink crimp connectors in household electrical systems, homeowners can ensure safe, reliable, and durable electrical connections for their lighting, appliances, and DIY projects, all while preventing common electrical issues like short circuits or water damage.

MARINE USES

Marine environments present unique challenges to electrical systems due to constant exposure to moisture, saltwater, and harsh weather conditions. For boats, yachts, and other watercraft, ensuring reliable and durable electrical connections is vital for both safety and performance. Heat shrink crimp connectors are especially well-suited for marine applications because they provide the extra protection needed to prevent corrosion, ensure waterproofing, and create long-lasting electrical connections even in the most demanding conditions.

Step-by-Step Guide for Installation in Marine Environments:

Preparation:

As with any electrical project, begin by stripping the insulation off the wires to expose enough bare wire to fit into the crimp connector. Be careful not to strip too much of the wire, as it could result in an unstable connection. For marine applications, make sure the wires are clean and free from any corrosion or dirt before starting.Choosing the Right Connector:

In marine environments, it’s crucial to select heat shrink crimp connectors that are specifically designed for use in such conditions. Choose connectors made from materials that are resistant to corrosion and designed to handle higher humidity and saltwater exposure. Many marine-grade connectors come with a special sealing ring that ensures a waterproof seal when heat is applied. Be sure to select the correct size to match the wire gauge.Crimping the Wires:

Insert the stripped wire into the connector, ensuring it is inserted fully but not too deeply. Use a crimping tool to secure the wire to the connector. A tight, firm crimp is necessary to ensure a stable, strong electrical connection. Pay particular attention to the connection’s firmness, as any looseness could lead to unreliable performance or intermittent failures in marine environments.Shrinking the Tubing:

After the crimp is secure, slide the heat shrink tubing over the crimped area. The key to a proper marine connection is ensuring that the tubing shrinks tightly and forms a perfect seal around the connector. Use a heat gun to apply even heat to the tubing until it shrinks completely and seals the connection tightly. This process ensures that no water, salt, or debris can penetrate the connection, reducing the risk of corrosion or electrical short circuits.Testing the Connection:

Once the heat shrink tubing has fully shrunk, gently tug on the wires to ensure they are firmly secured. You should also check the connection for any visible gaps in the seal or areas where moisture could enter. Using a multimeter, verify the continuity of the connection to ensure it is functioning properly and safely.

Why Marine Applications Benefit from Heat Shrink Crimp Connectors:

Waterproof and Corrosion Resistance: Marine environments are notoriously harsh on electrical components. Heat shrink crimp connectors are designed to resist corrosion caused by saltwater and moisture. The added waterproof seal provided by the heat shrink tubing ensures that electrical connections remain dry and functional, even in the wettest conditions.

Enhanced Durability: The combination of crimping and heat shrink tubing creates a highly durable connection that can withstand the physical stresses found in marine environments, such as vibrations, waves, and constant movement. These connections are less likely to loosen over time compared to standard connectors.

Prevents Short Circuits: Moisture is one of the most significant threats to electrical systems on boats and marine vessels. By using heat shrink connectors, you create a sealed environment around the electrical connection, preventing water from causing shorts or failures in the circuit.

Reduced Maintenance Costs: Properly sealed, long-lasting connections can significantly reduce the amount of maintenance and repair work needed. This makes heat shrink connectors a cost-effective solution over time, especially for marine electrical systems that require frequent inspections.

Common Marine Applications for Heat Shrink Crimp Connectors:

Boat Lighting Systems: Whether it’s for deck lights, interior lights, or navigation lights, heat shrink crimp connectors ensure that your lighting circuits stay secure and waterproof, even when exposed to heavy splashing or rain.

Electrical Systems for Motors and Pumps: Marine engines, bilge pumps, and water systems require reliable electrical connections to keep everything functioning smoothly. Heat shrink connectors help maintain these connections, even when exposed to water or humidity.

Marine Electronics: For sensitive electronics such as GPS units, sonar systems, or radios, using heat shrink crimp connectors ensures that electrical connections remain safe from water damage, salt corrosion, and environmental stress.

Battery Connections: Secure, corrosion-resistant battery connections are essential in marine applications. Heat shrink crimp connectors prevent corrosion on battery terminals, ensuring optimal performance and safety.

Additional Tips for Marine Use:

Choose Marine-Grade Components: Always use connectors specifically labeled as marine-grade, as these are designed to handle the extreme conditions of saltwater, humidity, and temperature fluctuations.

Ensure Proper Seal: When shrinking the tubing, ensure that the heat shrink tubing covers not just the crimp but also a bit of the wire insulation, forming a full seal to protect the wire and the connection from environmental elements.

Inspect Regularly: While heat shrink connectors are highly durable, it’s always a good practice to inspect marine electrical connections regularly for any signs of wear, corrosion, or physical damage—especially after long periods of use or exposure to extreme conditions.

Use a Quality Heat Gun: When shrinking the tubing, avoid using an open flame such as a lighter or match, as it can cause uneven heating or even damage the connector. A heat gun is ideal for providing uniform, controlled heat.

By using heat shrink crimp connectors in marine applications, boat owners and marine professionals can ensure their electrical systems remain reliable, safe, and efficient in even the toughest conditions. These connectors offer an effective solution for preventing electrical failures caused by moisture, corrosion, and wear, providing peace of mind and enhanced performance on the water.